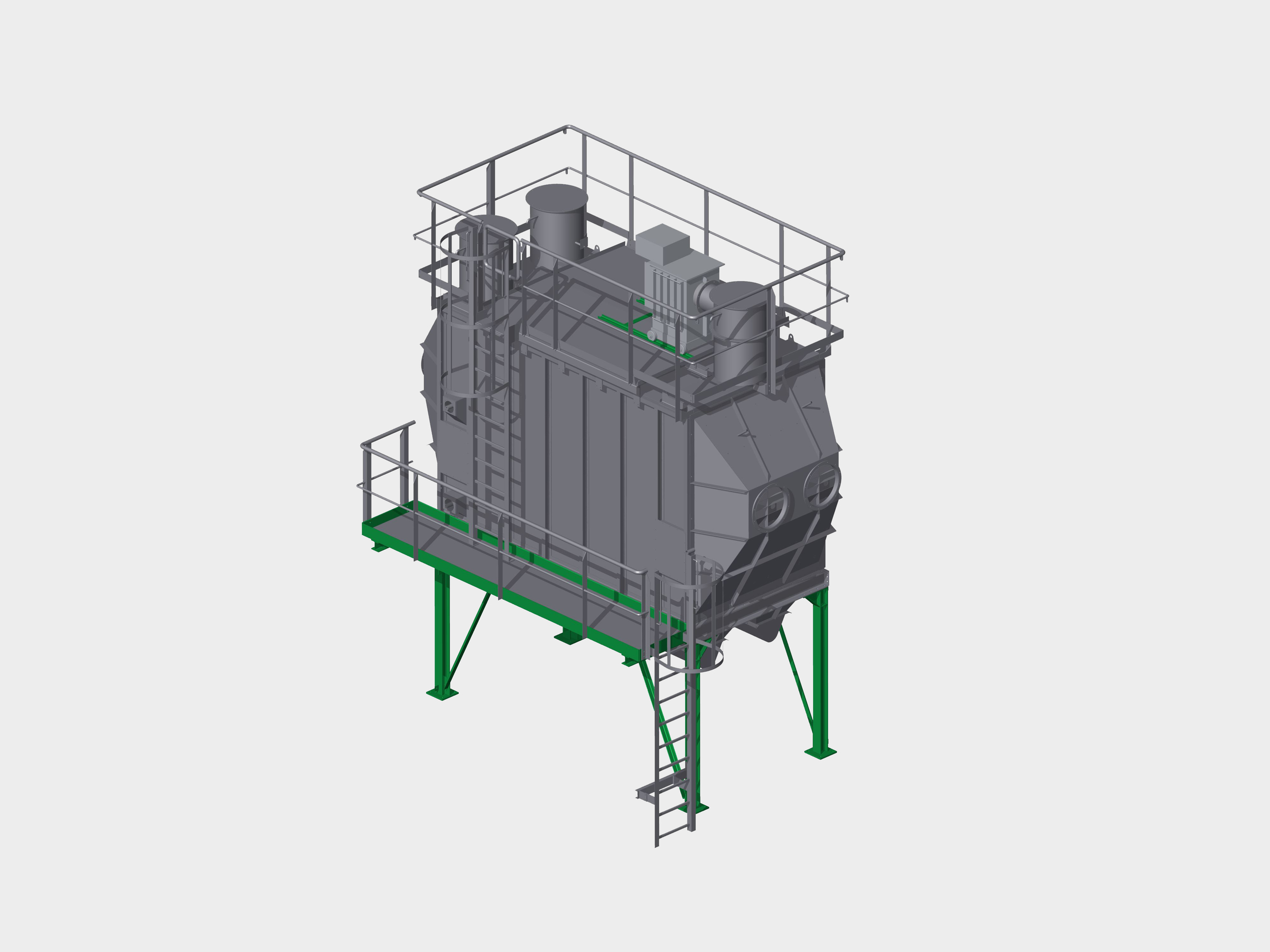

Dry electrostatic precipitator

The SaveEnergy dry electrostatic precipitator is a high-capacity separator that was developed with the specific aim of achieving minimal operating costs and maximised separation efficiency with an availability of around 99%.

Low maintenance costs

- Rapid and low-cost maintenance is achieved thanks to good accessibility achieved through platforms, walkways and large access openings.

- No manual maintenance is required for the dust collector hoppers, which are designed with steep sides to prevent bridging.

- Affordable support with remote access as standard.

Low running costs

- Low electricity consumption thanks to SaveEnergy energy management

Low capital costs

- Minimal building costs thanks to compact size with the SaveEnergy double hopper construction

- Compact and cost-efficient assembly thanks to optimal gas distribution through individual and flow-optimised perforated plates and guide plates.

The technology in detail

In the SaveEnergy dry electrostatic precipitator (commonly known as an electrofilter), particulate matter is separated from the flue gas using the force of an electrostatic charge. The electrically neutral dust particles are charged by discharge electrodes. The force of the electrical charges sends the particles towards the collecting electrode and thereby discharges them from the gas flow.

The SaveEnergy dry electrostatic precipitator is designed as a plate separator. A controlled high-voltage field of up to 70 kV is generated at the discharge electrodes. A high field-strength is created directly around the discharge electrodes. In this active zone, the free electrons are highly accelerated (gas discharge). This so-called ionisation is associated with a slight glow, which is known as a corona. The corona discharge at the ends of the discharge electrodes creates gas ions which adhere to the dust particles and impart an electrical charge to them.

The charged particles are then drawn into the separating chamber through which the gas is flowing, and transported, across the direction of the gas stream, between the discharge and collecting electrodes to the electrically earthed collection plates (anodes), and thus separated from the gas stream. This flow, which moves from the active zone through the passive zone to the collecting electrode, is known as “electric wind”.

The separated particles form a layer of dust on the collecting plates. Since the collecting plates are earthed, the dust particles lose their charge and can be cleaned away mechanically. Hammer blows from two rappers are delivered at differing pre-set intervals to both the collecting plates and the discharge electrode frames. The dust particles are loosened by the mechanical shock waves and fall into the collecting hoppers. The heating system operates continuously throughout the whole process, thus ensuring very high availability.